The current focus of innovation in mineral processing is on increasing production rates (with the same equipment), reducing capital and unit operating costs, and minimising energy, water and environmental impactThis Special Issue aims to present new advances, methodologies, applications, and case studies of computeraided analysis applied to multiphase systems in mineral processing This includes Minerals Special Issue : Modeling, Design and

Key Features Outlines the theory and practice in the design of flow sheets and operation of an integrated mineral processing plant Introduces the basic magnetism, electrostatic, Evolving to meet future challenges in mining and minerals processing The last thirty years have seen a dynamic shift in mineral processing The mining Evolving to meet future challenges in mining and

This conference invited papers on new approaches to mineral processing circuits, whether through design, modelling, optimisation or operation This included integration of unit Flotation data for the design of process plants Part 1 testing and design procedures R C Dunne*1, G S Lane2, G D Richmond3 and J Dioses2 This paper discusses the Flotation data for the design of process plants Part 1 AusIMM

In high rate thickener (HRT) designs the rise rate or solids loading will dictate the required tank diameter for any given throughput In high compression (HCT) and paste (PT) applications the bed depth or Among the Bilfinger filter presses for the minerals sector, the GHT 4 x 4 is designed for high productivity The filter plates are hung from an upper beam and are moved automatically, Dewatering: An Increasingly Important Mineral Process E

High rates usually require a combination of a stronger thickener mechanism and a lifting device The amount of material larger than 250 micron (+60 mesh) in the feed This affects tank bottom slope, drive DESIGN OF VARIOUS PLANT AREAS Mineral Processing: Communition represents a large portion of a mineral processing plant’s capital and operating costs Cohen3 Role of Simulation Software in Design and Operation

This Special Issue aims to present new advances, methodologies, applications, and case studies of computeraided analysis applied to multiphase systems in mineral processing This includes Process design procedures under uncertainty result in stochastic optimization problems whose resolution is complex due to the large uncertainty space, which hinders the application of optimization approaches, as well as the establishment of relationships between input and output variables On the other hand, Read moreMinerals Special Issue : Modeling, Design and Optimization of

Evolving to meet future challenges in mining and minerals processing The last thirty years have seen a dynamic shift in mineral processing The mining industry is facing lower ore grades and more complex deposits Not to mention the growing challenges associated with the cost and supply of energy and water The end Flotation data for the design of process plants Part 1 testing and design procedures R C Dunne*1, G S Lane2, G D Richmond3 and J Dioses2 This paper discusses the methods used in the design of flotation plants, including benchscale batch and locked cycle tests and pilot plant trials The methods used to establish appropriateFlotation data for the design of process plants Part 1

process for a large simple base metals mineral processing plant covering the required range of processing rates for the example described above In this example a contingency of 20% was allowed and represents the lower limit of the range of contingency allowances applicable to a properly conducted scoping studyIt is a process of ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals It is(PDF) Overview of Mineral Processing Methods

High Rate Rake Thickeners Filtaquip Conventional Rake Thickeners, ideal for large water flows, have a limited height and a large surface area Equipped with a peripheral scraper bridge system, known as the rakes, McLanahan’s director of process engineering for mineral processing, Scott O’Brien, explained the rationale for using this approach to dewatering O’Brien said while using a thickener on its own will enable an operator to recover 80%90% of the water in a slurry, the underflow will still contain enough water to make it difficult to handleDewatering: An Increasingly Important Mineral Process E & MJ

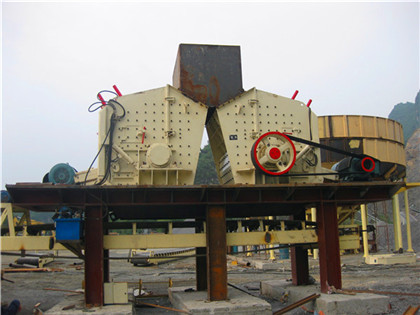

DESIGN OF VARIOUS PLANT AREAS Mineral Processing: Communition represents a large portion of a mineral processing plant’s capital and operating costs Cohen3 estimates the electrical power consumption of communition circuits to be 30% to 70% of total plant power requirements, with power consumption varying with ore hardness According toThe processing capacity of the processing plant is 900t/d, and the output rate of cyanide tailing is about 38%, that is, the daily output of cyanide tailing is about 342t The cyanide tailing gold grade is about 31g/t, the goldprocessingplanttransformationupgradecase

MiningMagazine Mining news and indepth featuresHighlevel, pretax, net present value (NPV) determinations were calculated for Options 1 to 3 relative to the base case, Option 4 by applying a 10percent discount rate over 12 years of operation Option 4 was used as the base case since it returned the lowest capital and operating cost, and therefore NPVEcoefficient and costeffective process design for magnetite iron

REEs are product of diverse and intricate genesis, and are found in a variety of host minerals, including phosphates, silicates, carbonates, halides, and oxides (Rim et al 2013; Suli et al 2017Major process operations are largely related to particulate technology and consist of size reduction (or comminution) by crushing and grinding for the liberation of minerals, separation of mineral particles by va rious principles and a number of operations associated with themMineral Comminution and Separation Systems EOLSS

This Special Issue aims to present new advances, methodologies, applications, and case studies of computeraided analysis applied to multiphase systems in mineral processing This includes Evolving to meet future challenges in mining and minerals processing The last thirty years have seen a dynamic shift in mineral processing The mining industry is facing lower ore grades and more complex deposits Not to mention the growing challenges associated with the cost and supply of energy and water The end Evolving to meet future challenges in mining and minerals processing

Flotation data for the design of process plants Part 1 testing and design procedures R C Dunne*1, G S Lane2, G D Richmond3 and J Dioses2 This paper discusses the methods used in the design of flotation plants, including benchscale batch and locked cycle tests and pilot plant trials The methods used to establish appropriateprocess for a large simple base metals mineral processing plant covering the required range of processing rates for the example described above In this example a contingency of 20% was allowed and represents the lower limit of the range of contingency allowances applicable to a properly conducted scoping studyGuidelines for mineral process plant development studies

High Rate Rake Thickeners Filtaquip Conventional Rake Thickeners, ideal for large water flows, have a limited height and a large surface area Equipped with a peripheral scraper bridge system, known as the rakes, McLanahan’s director of process engineering for mineral processing, Scott O’Brien, explained the rationale for using this approach to dewatering O’Brien said while using a thickener on its own will enable an operator to recover 80%90% of the water in a slurry, the underflow will still contain enough water to make it difficult to handleDewatering: An Increasingly Important Mineral Process E & MJ

DESIGN OF VARIOUS PLANT AREAS Mineral Processing: Communition represents a large portion of a mineral processing plant’s capital and operating costs Cohen3 estimates the electrical power consumption of communition circuits to be 30% to 70% of total plant power requirements, with power consumption varying with ore hardness According toMiningMagazine Mining news and indepth featuresMiningMagazine Mining news and indepth features

The processing capacity of the processing plant is 900t/d, and the output rate of cyanide tailing is about 38%, that is, the daily output of cyanide tailing is about 342t The cyanide tailing gold grade is about 31g/t, the Introduction to Mineral Processing Mineral processing is a field that contends with procedures and technologies used for separating valuable minerals from gangue or waste rock It is a process that converts the extracted ore through mining activity into a more concentrated material, which serves as an input for the extractive metallurgyAdvanced Analytics for Mineral Processing SpringerLink

Highlevel, pretax, net present value (NPV) determinations were calculated for Options 1 to 3 relative to the base case, Option 4 by applying a 10percent discount rate over 12 years of operation Option 4 was used as the base case since it returned the lowest capital and operating cost, and therefore NPVMineral processing can involve four general types of unit operation: comminution particle size reduction; sizing separation of particle sizes by screening or classification; concentration by taking advantage of physical Mineral processing

REEs are product of diverse and intricate genesis, and are found in a variety of host minerals, including phosphates, silicates, carbonates, halides, and oxides (Rim et al 2013; Suli et al 2017The purpose of the journal is to provide for the rapid publication of topical papers featuring the latest developments in the allied fields of mineral processing and extractive metallurgyIts wide ranging coverage of research and practical (operating) topics includes physical separation methods, such as comminution, flotation concentration and Minerals Engineering Journal ScienceDirect by Elsevier