Copper mining is usually performed using openpit mining, in which a series of stepped benches are dug deeper and deeper into the The mood was apprehensive as data scientists, metallurgists, and engineers from FreeportMcMoRan filed into the Inside a mining company’s AI transformation McKinsey

The processing equipment and process of the copper ore concentrator are as follows: When the copper ore enters the machine, after layers of processing, it Will get copper concentrate ore from twostage shaking tables This designed flowchart is suitable to process Oxide type and Sulfide type copper, and man Copper Ore Mining Plant Solution JXSC Machine

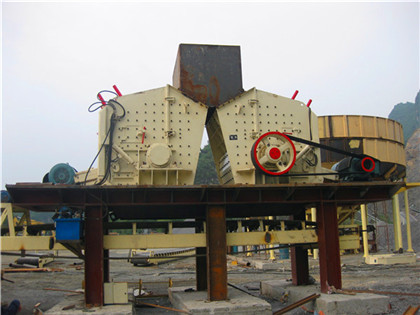

CRUSHING COPPER ORE The crushing section consists of two or three crushing stages with the second or third stages in either closed or open circuit with vibrating screens Generally, size of the 2 2 Mining Methods Left: Open Pit Mining Right: Underground Mining In each of these mining methods, various earthmoving equipment including shovels, dozers, hauling trucks, and loaders are used to remove and 2 Copper

Now chatting: leawaysschool/solutionhtmlContact Us: leawaysschool Mining Machinery copper ore concentrator It was condensed to produce sulfuric acid Copperhill (population 600) was born when the name of the Post Office at McCays was changed in 1908 Copperhill was burned nearly GMS Copper Basin Photos

Bulk ore sensing and sorting enables the preconcentration of the concentrator feed while simultaneously improving its consistency It sets a foundation for better performance in all subsequent operations delivering dividends by: Increasing resource utilization Adding throughput with no plant expansionCopper ore dressing equipment 1 Flotation machine Flotation is the most widely used method in copper mine production The copper ore pulp is stirred and aerated, and the ore particles adhere to How to Process Copper Ore: Beneficiation Methods

The classification equipment of copper ore concentrators mainly includes spiral classifiers and hydrocyclone The spiral classifier is primarily used for closedcircuit operation with ore grinding equipment or ore washing, dehydration, des, etc, and has a better classification effect on coarser particlesCopper Ore Processing Process 1The bulk copper ore material is uniformly fed into the jaw crusher by the vibration feeder for primary crushing 2The coarse copper ore is sent by belt conveyor to Copper Ore Processing Equipment Fote

Will get copper concentrate ore from twostage shaking tables This designed flowchart is suitable to process Oxide type and Sulfide type copper, and man other minerals, such as rock gold, rock Chrome ore, rock coltan ore, rock tin ore, rock Mn ore, rock zinclead, etcThree (3) ore types are fed to the Assarel Concentrator Plant which differ in terms of their particle sizes and mineral composition The ore blend contains secondary quarcites,Mineral Processing Abstracts COPPER 2022

Type: Flotation Separator Voltage: 380V Weight: 1T Material: Stainless Steel Material Feature: Heat Resistant Certification: ISO9001:2008, ISO9001:2000, CE to legaojm/m account on m/ n copper flotation cell machine · legaojm/m

Il Cile Copper Mining Equipment/Froth Flotation Machine da vendere,Trova i Dettagli su Estrazione mineraria di rame del Cile, Lancio del minerale metallifero della roccia da Il Cile Copper Mining Equipment/Froth Flotation Machine da vendere Jiangxi Shicheng Yongsheng Ore Processing Equipment Manufacturing Co, LtdOre processing flow: 1 Crushing: Use stone crushers to crush the copper ore to 0~5mm or 0~9mm 2 Washing: Use a spiral classifier to wash away the clay and screen out copper ore with a qualified particle size 3 Copper Ore Processing Plant Fote Machinery

lithological structure of the ore, metal concentration in the ore, efficiency of processing, and revenues from the sale of copper concentrates or metals on the world market of nonferrous metals 2 Brief description of the copper deposit Polish copper mining is well known in the world because of Poland’s share in the global metals marketCopper is processed in several stages from extraction and crushing of the ore to electrolytic refining, which allows obtaining 9999% pure Copper Cathodes The beginning for all copper is to mine sulfide and oxide ores through digging or blasting and then crushing it to walnutsized piecesCopper Concentrates Cargo Handbook the world's largest

2 2 Mining Methods Left: Open Pit Mining Right: Underground Mining In each of these mining methods, various earthmoving equipment including shovels, dozers, hauling trucks, and loaders are used to remove and transport the ore However, the first step is to loosen the rock in the ore body so that it can be moved and processedFigure 2: Overview of a typical beneficiation process at a concentrator Sulfidic copper ores are too dilute for direct smelting Smelting these materials would require too much energy and very large furnace capacities The copper ore coming from the mine (05 1 % Cu) must be concentrated by beneficiationCOPPER Copper production TU Delft

Bulk ore sensing and sorting enables the preconcentration of the concentrator feed while simultaneously improving its consistency It sets a foundation for better performance in all subsequent operations delivering dividends by: Increasing resource utilization Adding throughput with no plant expansionAccording to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide That is, sulfide ore, containing less than 10% copper oxide; oxidized ore, containing more than 30% copper oxide; mixed ore, containing 10% to 30% of copper oxide Copper sulfide ore flotationCopper Processing Equipment, Process Flow, Cases JXSC Machine

The classification equipment of copper ore concentrators mainly includes spiral classifiers and hydrocyclone The spiral classifier is primarily used for closedcircuit operation with ore grinding equipment or ore washing, dehydration, des, etc, and has a better classification effect on coarser particlesCopper Ore Concentrator 6,385 products found from 130 Copper Ore Concentrator manufacturers & suppliers Product List ; Supplier List; View: List ViewCopper Ore Concentrator manufacturers & suppliers

Ore processing flow: 1 Crushing: Use stone crushers to crush the copper ore to 0~5mm or 0~9mm 2 Washing: Use a spiral classifier to wash away the clay and screen out copper ore with a qualified particle size 3 Three (3) ore types are fed to the Assarel Concentrator Plant which differ in terms of their particle sizes and mineral composition The ore blend contains secondary quarcites,Mineral Processing Abstracts COPPER 2022

Type: Flotation Separator Voltage: 380V Weight: 1T Material: Stainless Steel Material Feature: Heat Resistant Certification: ISO9001:2008, ISO9001:2000, CE to legaojm/m account on m/ n copper flotation cell machine · legaojm/m

Il Cile Copper Mining Equipment/Froth Flotation Machine da vendere,Trova i Dettagli su Estrazione mineraria di rame del Cile, Lancio del minerale metallifero della roccia da Il Cile Copper Mining Equipment/Froth Flotation Machine da vendere Jiangxi Shicheng Yongsheng Ore Processing Equipment Manufacturing Co, Ltdlithological structure of the ore, metal concentration in the ore, efficiency of processing, and revenues from the sale of copper concentrates or metals on the world market of nonferrous metals 2 Brief description of the copper deposit Polish copper mining is well known in the world because of Poland’s share in the global metals marketWMS205 Malewski Production of copper f Institute of Physics

Copper ore concentrator: crusher, grinding mill and froth flotation machine are used in copper concentrate process for beneficiation production Gold Concentrators Prospecting Equipment > Gold Concentrators Gold Concentrators Final cleanup The Desert Fox spiral gold panning machine from Camel Mining ProCamel 24Copper Ore Processing Plant Hengcheng offers turnkey solutions for Copper flotation Plant We are one of the leading project suppliers for Copper flotation Plant and we work closely with our customers to fulfill their specific needs for customized package solution Specialized in the fabrication of these machines for 25 years and this enablesCopper Ore Processing Plant Hengcheng Mining Equipment Co,ltd

2 2 Mining Methods Left: Open Pit Mining Right: Underground Mining In each of these mining methods, various earthmoving equipment including shovels, dozers, hauling trucks, and loaders are used to remove and transport the ore However, the first step is to loosen the rock in the ore body so that it can be moved and processedFigure 2: Overview of a typical beneficiation process at a concentrator Sulfidic copper ores are too dilute for direct smelting Smelting these materials would require too much energy and very large furnace capacities The copper ore coming from the mine (05 1 % Cu) must be concentrated by beneficiationCOPPER Copper production TU Delft