This research paper contains the design aspects and analysis of the gear box used in the ball mill The ball mill is used for the conversion of the raw stone Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding modes, usable volumes and Ball Mill RETSCH powerful grinding and homogenization

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis The axiBall mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼” to 15” The particles to be milled are trapped between the grinding Ball Mill Application and Design Paul O Abbe

roller grinding mill KVS 280 horizontal stone for fruit Output: 8 t/h 12 t/h Motor power: 4 kW Machine length: 1,562 mm Roller mill for the crushing of berries and stone fruits Ball Mills Capacity】 0290 T/H Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity Max Ball Mills Industry Grinder for Mineral Processing JXSC

Working principle of Stone ball mill: Ball mill is a horizontal rotating device transmitted by the outer gear The materials are transferred to the grinding chamber through the quill 34 TY ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis Ball Mill Working Principle And Main Parts Pages

Ball Mill Principle The ball mill machine is mainly composed of cylindrical cylinder, end cover, bearing and big gear ring Cylinder: The cylinder is filled with a ball mill grinding media (steel balls or steel cylpebs) with a This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder Ball mill is a cylindrical device that used to grind and blend(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼” to 15” The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attritionBall Mill Application and Design Paul O Abbe

roller grinding mill KVS 280 horizontal stone for fruit Output: 8 t/h 12 t/h Motor power: 4 kW Machine length: 1,562 mm Roller mill for the crushing of berries and stone fruits The KVS 280 crushing mill was developed to produce the Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills Ball Mill Drive Options At Orbis Machinery we offer a variety of drive options to suit your needs: Standard shaft mount reducer and belt drive Gearwheel and pinionIndustrial Ball Mills: Steel Ball Mills and Lined Ball Mills Orbis

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world Since this minireview mainly focuses on the conditions applied for the prepKey benefits High reliability over a century of experience with 4000+ ball mills installed globally Large throughflow area ensures low pressure drop across the mill Horizontal slide shoe bearing design allows much Energy efficient cement ball mill from

Ball Mill Principle The ball mill machine is mainly composed of cylindrical cylinder, end cover, bearing and big gear ring Cylinder: The cylinder is filled with a ball mill grinding media (steel balls or steel cylpebs) with a How to Mount a Ball Mill If adequate overhead crane facilities are available, the heads can be assembled to the shell with the flange connecting bolts drawn tightly Furthermore, the liners can be in Ball Mill Maintenance & Installation Procedure

To ensure the stability of the mini ball mill, a ball mill base is design and fabricate to withstand the weight of the rotating jar, motor and gears After a few hours, stop the miniThis project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder Ball mill is a cylindrical device that used to grind and blend(PDF) DESIGN AND FABRICATION OF MINI BALL

Planetary Ball Mill PM 400 The PM 400 is a robust floor model with 4 grinding stations and accepts grinding jars with a nominal volume from 12 ml to 500 ml It processes up to 8 samples simultaneously which results in a The size of the ball mainly depends on the particle size of the material to be ground, and the diameter and speed of the mill can be considered appropriately Formula (115) is an empirical formula for spherical diameter and feed size dmax — The maximum diameter of steel ball, mm; amax — the maximum size of feeding granularity, mmBall Mill Parameter Selection & Calculation JXSC Machine

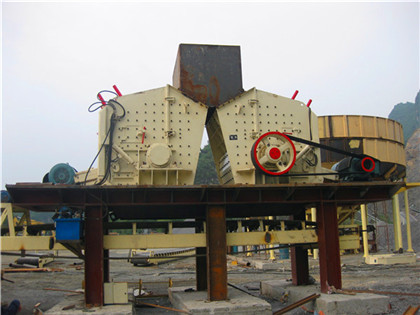

Typically, the mini ball milling device consists of a cylindrical vessel mounted on an appropriate basis at both ends which allows rotation of the vessel around the center axis The mill is driven by long high density mild steel shaft and powered by an AC motor mounted to the base of the ball millNew Design Construction Equipment Stone Crushing Jaw Crusher $50000 / set 1 set (Min Order) Professional Iron Oxide Rock Grinding Ball Mill Machine For Sale / set 1 set (Min Order) Professional Iron Ore Puzzolana Psgb0917 Cone Crusher / set 10 set (Min Order) Good Quality Pe600x900 Hard Stone Dolomite Jaw Crusher / setHenan Hongji Mine Machinery Co, Ltd Ball Mill, Stone Crusher

Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼” to 15” The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attritionPlanetary Ball Mill PM 400 The PM 400 is a robust floor model with 4 grinding stations and accepts grinding jars with a nominal volume from 12 ml to 500 ml It processes up to 8 samples simultaneously which results in a Planetary Ball Mill PM 400 RETSCH powerful and

ball mill horizontal for cement stone Final grain size: 200 µm Rotational speed: 70 rpm Machine length: 120 cm a laboratorygrade ball mill designed to obtain small particle size samples for testing standards This powerful device is capable of grinding a wide range of materials, including hard and medium hard bauxite, samot,The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world Since this minireview mainly focuses on the conditions applied for the prepBall milling: a green technology for the preparation and

Key benefits High reliability over a century of experience with 4000+ ball mills installed globally Large throughflow area ensures low pressure drop across the mill Horizontal slide shoe bearing design allows much Henan Hongji Mine Machinery Co, Ltd Ball Mill, Stone Crusher 4YRS Home Products Profile Contacts Energy Saving 250x1200 Gypsum Rock Stone Jaw Crusher Price $5,00000 / set 1 set (Min Order) China Mine Stone Cone Crusher Breaker Machine Price $10,00000 $100,00000 / set 10 set (Min Order)Henan Hongji Mine Machinery Co, Ltd Ball Mill, Stone Crusher

To ensure the stability of the mini ball mill, a ball mill base is design and fabricate to withstand the weight of the rotating jar, motor and gears After a few hours, stop the miniThe ball mill machine is mainly composed of cylindrical cylinder, end cover, bearing and big gear ring Cylinder: The cylinder is filled with a ball mill grinding media (steel balls or steel cylpebs) with a diameter of 25mm Ball Mill Machine ball mills supplier

How to Mount a Ball Mill If adequate overhead crane facilities are available, the heads can be assembled to the shell with the flange connecting bolts drawn tightly Furthermore, the liners can be in Ball mill is one of the most variable and effective grinding machines which is mainly applied for further grinding the crushed materials Compared with other grinding mills, the variety of grinding modes, available grinding tool materials, and flexible production capacity make ball mill grinders the perfect match for a vast range of applications, such as cement industry, BALL MILL GRINDER Industrial Ball Mill For Sale

ball grinding mill L14 series with rods horizontal stone Rotational speed: 42 rpm 69 rpm Rod / Ball Mills are Rubber coated and manufactured in Double and Triple Roll models The Rolls are 120 mm diameter x 1200 A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall Mill an overview ScienceDirect Topics

Understanding the hardness and chemistry is a crucial application qualifier The sixrow is the final option before getting into higher cost, specialized fine or ultrafine grinding equipment, such as ball mills, vertical roller mills, or jet mills Final crushed product sizes down to 80% passing 200 mesh are possible Cage Mill Maintenance065 to 90 TPH Ball Mills Ball mill is a key equipment for grinding materials thus grinding ball mills are widely used in the mining beneficiation process, and it has a wide range of suitable grinding mineral and can works on wet and dry grinding processing our JXSC's ball mills are perfectly used for ores such as gold, iron, zinc oreBall Mill for Sale Grinding Machine JXSC Mining